next-generation manufacturing solutions

VDL VDS Technische Industrie is known for its highly automated and robotized production processes. With a team of process engineers, VDL VDS constantly monitors and investigates the latest trends and developments in the field of metalworking. This includes, in particular, the automation and robotization of (internal) processes. By implementing the latest technological developments in our machinery, we are able to minimize the costs along with targeted investments.

Benefits of automation and robotization:

- Reducing margins of error.

- Increasing efficiency.

- Realizing cost savings.

- Ensuring competitiveness.

Flexibility

Targeted investments enable us to offer customized solutions. Some of our automated production processes are product-specific, while others can be used for multiple applications. This allows us to respond to our clients' needs, no matter how challenging they might be. This flexibility ensures that we can always find or develop a suitable production process for your specific requirements.

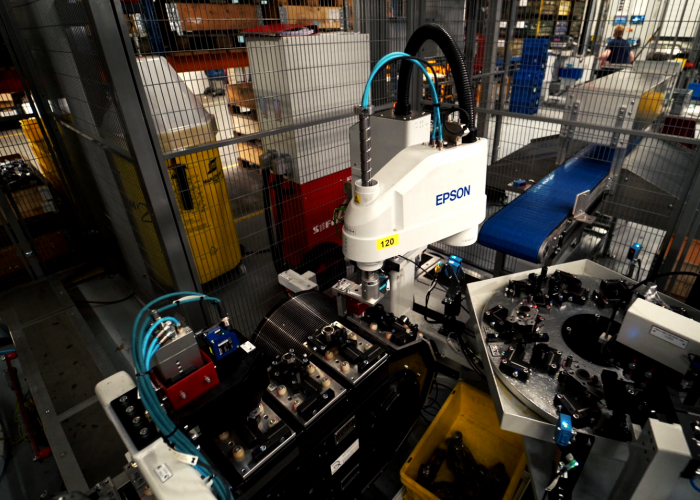

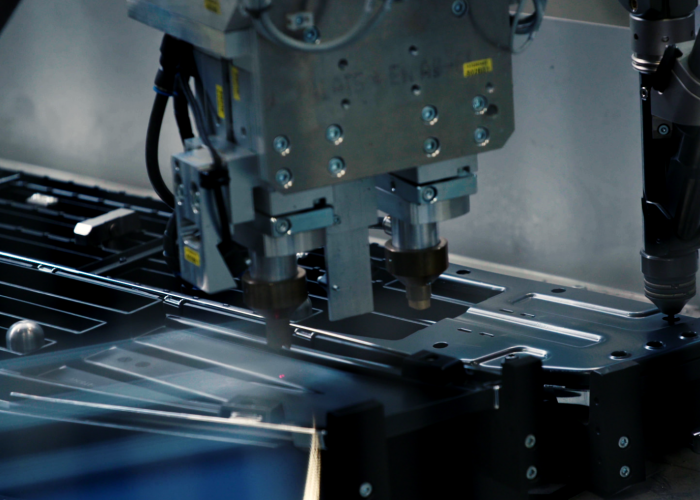

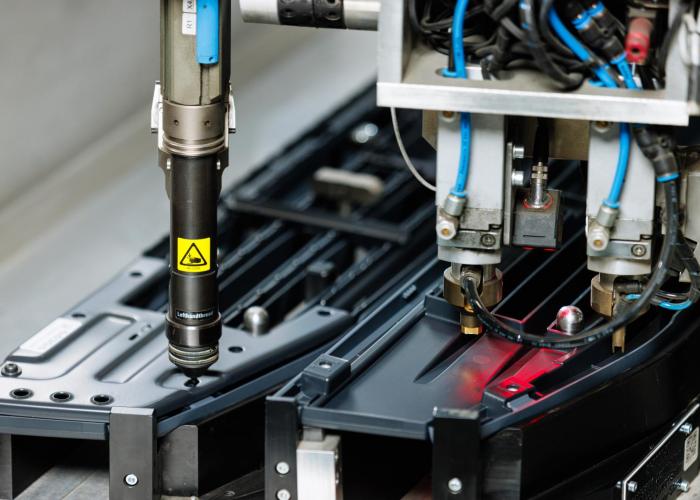

Examples of automation lines present at VDL VDS:

- (Product-specific) Robotic assembly line with clinching, welding, wire tapping, and 100% inspection;

- (Product-specific) Robotic milling carousel for finishing in-house stamped metal parts;

- (Multi-purpose) Automatic packaging line for packaging in various types of packaging;

- (Multi-purpose) Robotic assembly line for mounting plastic to steel parts using various fasteners;

- (Multi-purpose) Transfer system for inserting and removing hydraulically formed parts in one or more forming operations;