Stamping

up to 1500 Tons press force

general information

What is metal stamping?

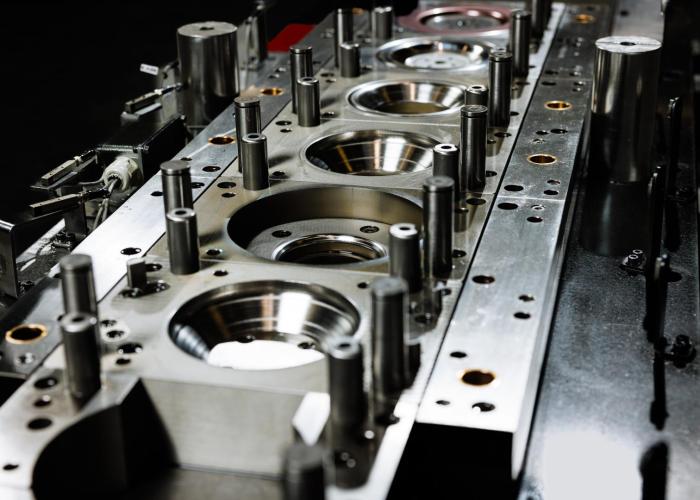

Stamping is a highly (cost) efficient technique for forming metal. The process enables us to create various shapes, holes, and other modifications in metal, using a specially designed production tool. The combination of sufficient pressing force and the use of the production tool makes it possible to realize the desired shape with extreme precision. This type of tool, known as a progressive die, combines cutting, bending, and drawing operations in a single tool. This offers an advantage over traditional and manual bending.

Stamping is often carried out using a coil, a roll of metal that is unrolled through the tool during the process. With each press stroke, a specific operation is performed to the metal, resulting in the desired end product.

What are the benefits of stamping?

1. Efficiency: Stamping is a very fast process. Large quantities of the same products can be produced in a short period of time.

2. Precision: Stamping makes it possible to achieve complex shapes and precise dimensions. The production tools guarantee precision, enabling consistent production.

3. Material savings: The material is manufactured from a sheet or strip, minimizing waste.

4. Repeatability: Stamping is the most suitable method for mass production due to its consistent production method.

5. Low costs: Stamping is known as the most cost-effective production method. The initial investment in the production tools pays for itself.

STAMPING AT VDL VDS

VDL VDS Technische Industrie is specialized in the production of medium and large batches. The extensive range of presses offers the possibility of stamping with a force of up to 1500 tons. This allows products with a material thickness of up to 10 millimeters to be produced.

Whether it concerns a new product concept or an already existing product, VDL VDS supports and guides you throughout the entire process with a team of experts, with the aim of keeping the cost price to a minimum. Thanks to its many years of experience, VDL VDS has all the knowledge and expertise in-house to produce even the most complex products within minimal tolerances.

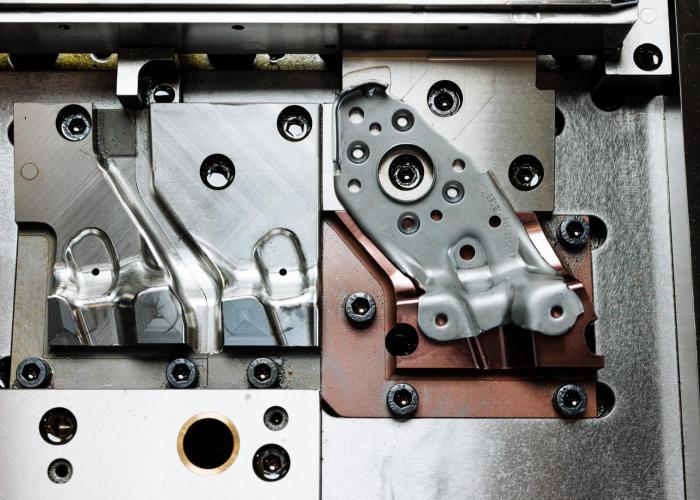

The necessary progressive dies are designed, assembled, and maintained 'in-house' at VDL VDS.

Nuts, Inserts & Wire Forms

VDL VDS has the capability to add nuts, wire forms, or other 'inserts' to the product during the stamping process. Avoiding the need for these operations to be carried out separately. This increases speed, reduces the risk of errors, and guarantees reproducibility.

Packaging

The use of self-developed automatic packaging machines, minimizes handling and ensures that products are produced and shipped in the correct quantities and packaging specified by the customer. All this contributes to the most competitive possible cost price and the highest possible quality.

Additional processing needed?

Stamping is often the first step in our process chain. Thanks to its extensive range of competencies, VDL VDS can further process the product. This includes, for example, deburring/degreasing or applying a surface treatment, also welding and/or assembly are among the possibilities. If desired, VDL VDS can act as a 'one-stop shop' for all your production requests.

Do you have a question or are you looking for additional information?

Get in touch with one of our specialists:

Couldn't find what you were looking for?

You could also use our search engine: