3d-laserCutting

general information

Wat is 3D-lasersnijden?

3D-lasersnijden wordt met name gebruikt om overtollig materiaal te verwijderen en/of (een) gaten (patroon) in allerlei vormen in een bestaand product toe te voegen. Derhalve is 3D-lasersnijden vaak complementair aan het hydraulisch vormen van metaal.

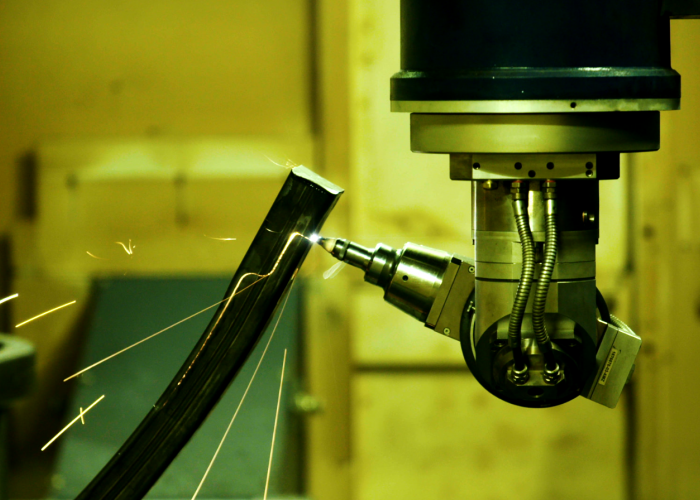

Anders dan een 2D-laser, waarmee enkel contouren (vlakken platen) kunnen worden bewerkt, heeft een 3D-laser een computergestuurde roterende laserkop. Een zeer nauwkeurige laserstraal snijdt het materiaal in de gewenste vorm. Met 3D-lasersnijden kunnen ontwerpen met complexe vormen uiterst gedetailleerd gerealiseerd worden.

3D-LASERCUTTING AT VDL VDS

Due to the low labor intensity, high accuracy, and short lead times, 3D laser cutting is a popular and relatively inexpensive method for reworking products. With our 3D laser carousels positioned directly behind the hydraulic presses, the hydraulically formed products can be processed directly and without additional handling into the desired (end) shape.

At VDL VDS, we use 3D laser cutting to process products with a maximum material thickness of 4 millimeters within a range of 4 meters wide x 1.5 meters deep x 0.75 meters high.

Laserwelding

With an exchangeable laserhead, VDL VDS also offers the option of laser welding. Some advantages of laser welding are:

- High accuracy: Laser welding is performed with a highly accurate laser beam, which can work much more precisely than traditional welding.

- Less heat input: Laser welding causes less thermal deformation than traditional welding, reducing the risk of damage or deterioration of the surrounding material.

- Faster: Compared to traditional welding, laser welding is a more efficient production method.

- No material addition: Laser welding does not always require the addition of material, as is the case with traditional welding (welding wire).

Additional processing needed?

Thanks to its extensive range of competencies, VDL VDS can further process the product. This includes, for example surface treatments, spotwelding, (robot)welding and/or (complete) assemblies. VDL VDS can act as a 'one-stop shop' for all your production requests.

Do you have a question or are you looking for additional information?

Get in touch with one of our specialists:

Couldn't find what you were looking for?

You could also use our search engine: