Robotwelding

general information

What is Robotwelding?

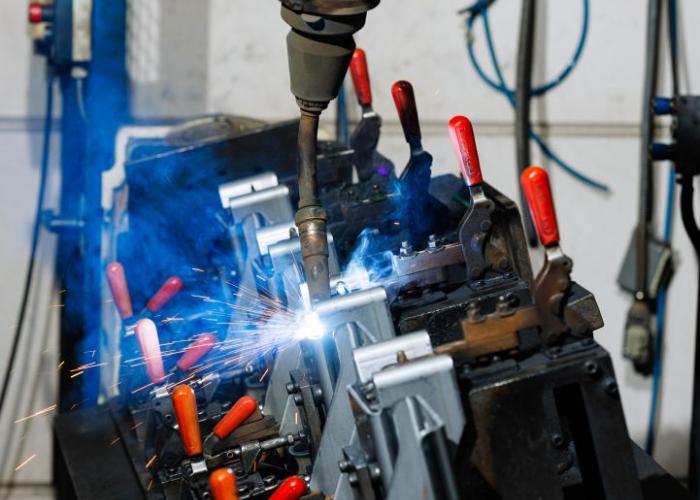

Robot welding is an automated welding process. Welding connects two or more parts together. The welding robots are pre-programmed according to the requirements of the product. Therefore, minimal personal involvement is required.

What are the benefits of robotwelding?

1. Accuracy & quality: The advantage of a programmed robot is that it guarantees a consistent production process; the robot performs the same action on every product, ensuring that the welding quality remains constant without the need to adjust the process.

2. Speed: Welding robots reduce lead times compared to traditional manual welding. The operator is involved in logistical tasks while the robot performs the welding operations. This results in an efficient production process.

3. Low costs: Due to minimal use of manpower, repeatable actions, consistent quality, and increased speed the cost price is reduced to a minimum..

ROBOTWELDING AT VDL VDS

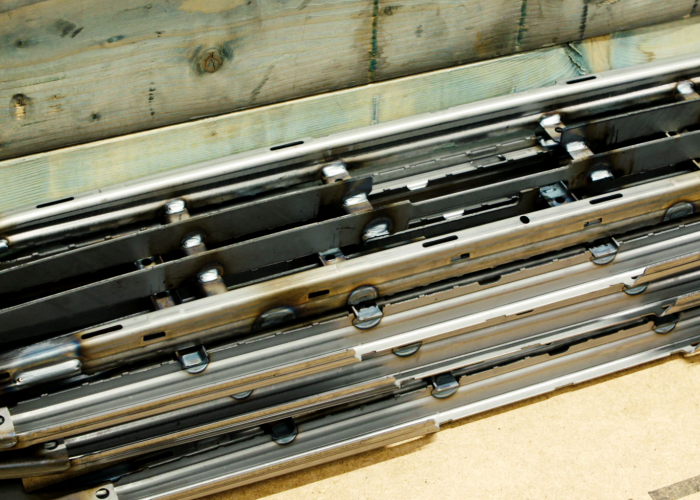

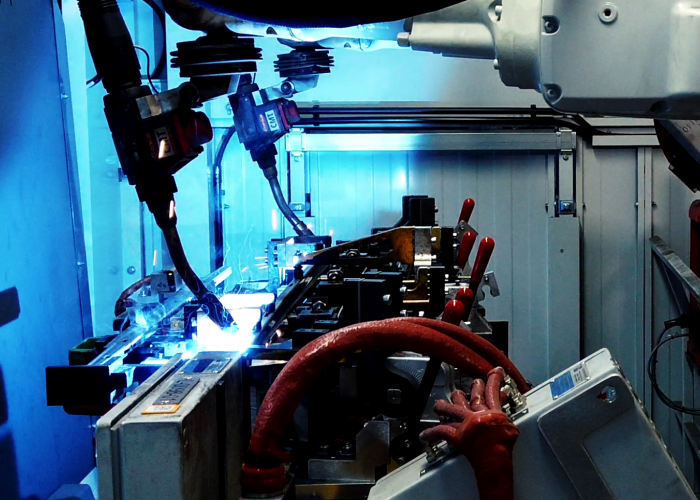

With multiple welding robots, VDL VDS Technische Industrie can perform welding operations on components with a material thickness of up to 12 millimeters. VDL VDS uses a detection system based on sensors and welding jigs to perform the welding operations. This guarantees optimum quality. The welding stations are designed in such a way that multiple products can be processed simultaneously. The welding stations and necessary software are configured in such a way that a specific product can be welded on every robot.

Weld burns can be checked and tested in-house through microscopic examination. Specific control jigs are used to accurately measure tolerances and monitor these closely during the production process. This ensures consistent, high quality.

Automation and robotization

With dedicated investments in automation lines and the use of robots, VDL VDS guarantees international competitiveness. The use of automation and robots also offers extra flexibility and ensures reproducible quality. The presence of a project-specific 3D welding carousel, general automated lifting aids for loading and unloading heavier parts, and the processing of welding operations in various project-specific automation lines are just a few examples of the possibilities developed by VDL VDS in order to guarantee its clients the most competitive prices and the highest possible quality.

Additional processing needed?

Deep drawing is often the first step in our process chain. Thanks to its extensive range of competencies, VDL VDS can further process the product. This includes, for example, 3D-lasercutting, applying surface treatments. Also welding and/or assembly are among the possibilities. If desired, VDL VDS can act as a 'one-stop shop' for all your production requests.

Do you have a question or are you looking for additional information?

Get in touch with one of our specialists:

Couldn't find what you were looking for?

You could also use our search engine: