product design phase

Build to print

Do you already have a validated product design and are you looking for a reliable partner for series production? VDL VDS is ready to support you.

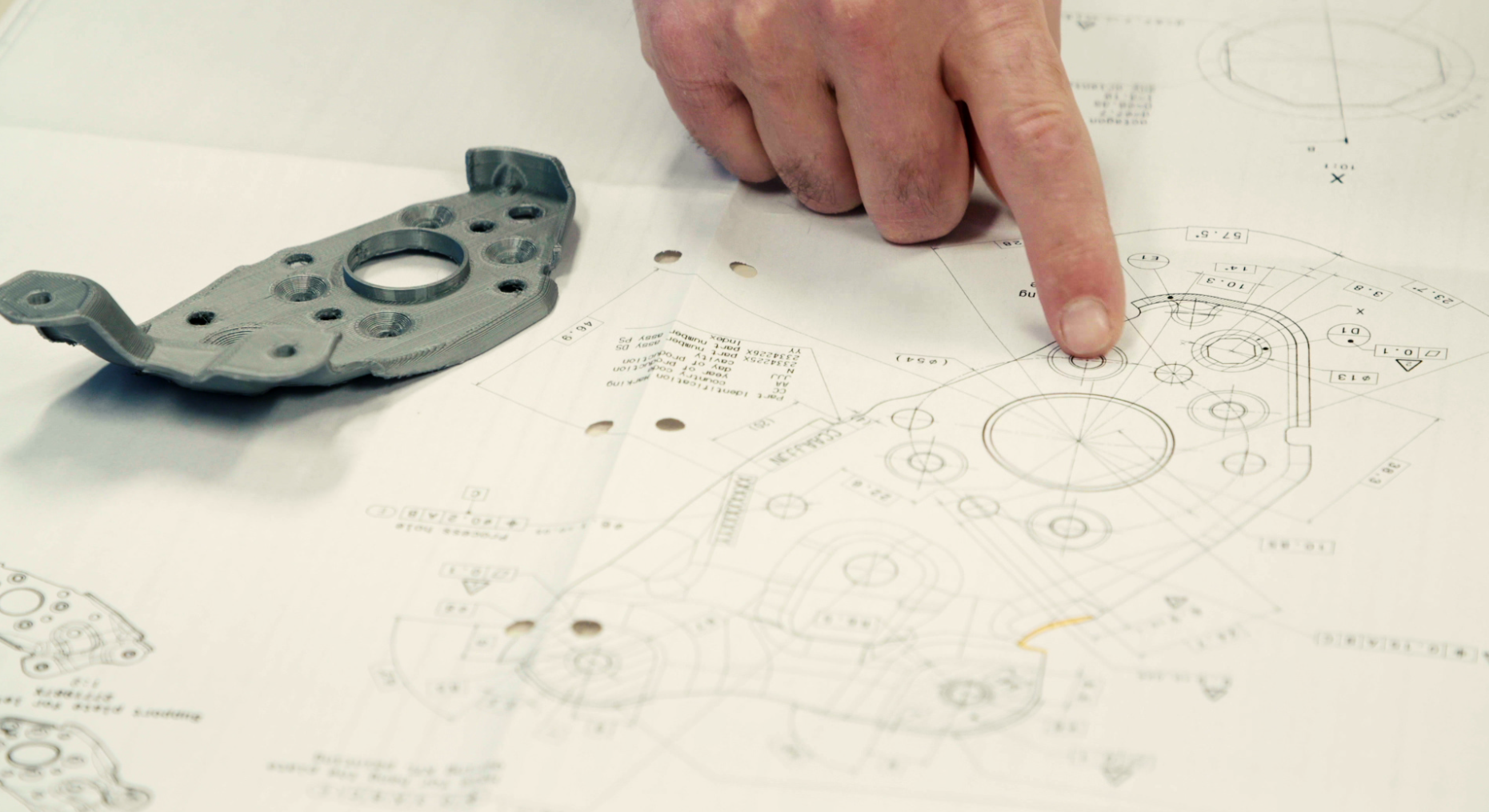

Our experienced product engineers will carefully review your technical drawings with you. Throughout this process, we actively think along and provide practical advice to help save time and reduce costs—without compromising on quality.

You remain in control of your product, while our specialists support you with their expertise and are ready to answer all your questions. Together, we ensure a smooth transition from design to production.

Build to SPec

Do you only have a rough sketch, an incomplete drawing, or just an idea in your mind? Our product engineers are happy to help you develop it into a complete and (re)producible design.

Together, we translate your requirements into a final technical design that’s ready for production. This design is then subjected to a thorough feasibility study, allowing us to test and validate the theoretical assumptions.

This way, we ensure that your idea is not only technically feasible, but can also be produced efficiently and cost-effectively.

tooling design phase

Once your design is finalized, our product engineers and tooling specialists translate your product drawing into an efficient and reliable tooling design. This production tool forms the foundation for a stable and reproducible end product.

In parallel, we coordinate the production process with you. Together, we determine the necessary steps and techniques to manufacture your product optimally. Where needed, we involve our process engineers to explore whether automation or robotics can contribute to cost reduction, increased output, and improved quality.

If desired, prototypes can also be provided at this stage, allowing you to validate the design before starting series production.

production phase

The first step in our process chain typically involves deep drawing or stamping of metal parts. The required tooling is designed and assembled during the preceding phase.

Before we begin series production, you will first receive the so-called First Out of Tool parts. These initial products from the tool are intended for your validation and approval, and offer the opportunity to further optimize our production process.

During this phase, you work closely with our quality engineers. Any potential improvements are discussed and implemented in consultation, ensuring the final result fully meets your expectations.

Once jointly approved, the tooling is released and we begin series production.

Additional information:

aDDitional processes (optional)

At VDL VDS, we also take care of any additional processing your product may require. Depending on your needs, we apply one or more supplementary processing methods – all carried out in-house to ensure maximum control and quality.

We can also handle post-processing treatments, such as surface finishing. For this, we collaborate with carefully selected partners who meet our high quality standards.

In short: VDL VDS is your flexible partner and one-stop shop for metalworking and product finishing – from raw shape to final product.

All processing methods at a glance:

Delivery phase

Thanks to our automated packaging systems, we can package your products directly into the final packaging you specify, with exactly the right quantity. VDL VDS works with customer-specific packaging: you decide how your products are delivered, and we think along with you.

Our experts are happy to advise you on the most sustainable and efficient packaging solutions, including optimal fill rates and material choices. Together, we ensure smart and responsible packaging.

VDL VDS’s advanced digital system integrates seamlessly with EDI. With support from our in-house Lean specialists, we keep inventory levels to a minimum at every point in the chain—without compromising delivery reliability. Just-In-Time deliveries are therefore standard.

As a one-stop shop, we can also take care of transport if desired. We work exclusively with carefully selected and certified transport partners who meet the highest standards in quality and safety. International deliveries are, of course, also possible.

Do you have a question or are you looking for additional information?